Processing centre for hydraulic pipes

Processing centre for hydraulic pipes

The experts for integrated fitting piping

Fundamentally revised, completely modular designed, functionally and ergonomically optimised - but thereby still as robust and reliable as ever. The new TUBOMAT generation defines its own standard as technological pioneer in hydraulic pipe processing.

Processing centre for hydraulic pipes

Hydraulic pipe processing engineered to perfection

Perfect Fitting Piping for 50 years and beyond — one for all!

Sawing / Deburring / Bending / Cutting ring preassembly / Flanging

As the market leader in hydraulic pipe machining, you will find the TUBOMAT wherever hydraulic specialists machine pipes. A modern design, numerous detail improvements and the optimization of work processes round off the machine professional.

Daniel Krämer

Area Sales Manager North

Do you have any questions about the TUBOMAT pipe processing center? I will be happy to answer them for you!

+49 2725 9540 48+49 151 15153582

TUBOMAT Processing centre for hydraulic pipes

The advantages

Increased flexibility

Growing system

Risk reduction

Cost reduction

TUBOMAT in numbers

Technical Data

Maximum bending performance (steel pipe)

ø 48,3 x 3,2 mm

Maximum bending radius

125 mm

Maximum bending speed

20 °/s

Bending accuracy

± 0,2 °

Usable lengths, approx.

2500 x 800 x 1400 mm

Weight, approximately

650 kg

Connected load

2,5 kW

- Completely modular structure

- Ergonomically optimised workflows

- Electronic bending angle control via SIMATIC Touch Panel for program mode or 4‑fold angle pre-selection, with storage facility for 80 bending programs

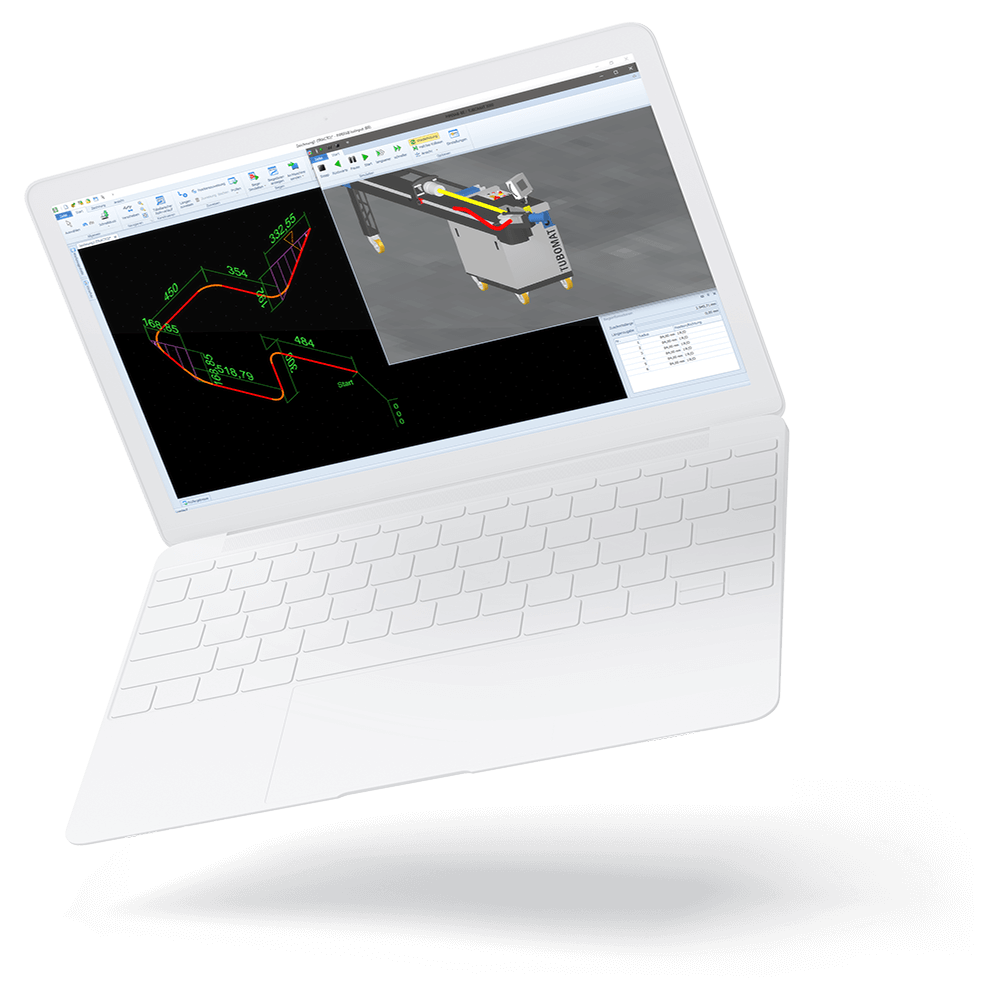

- Interface for pipe bending data import from the PIPEFAB software

- Exposed and compact bending head for maximum bending space

- Optimised bend tooling concept

- Hydraulic bending drive, approved operation by hand lever valve

- Hydraulic pipe clamping

- Hydraulic pressure die positioning

- Hydraulic mandrel retraction

- Modern design

- Machine mobile and flexible to use

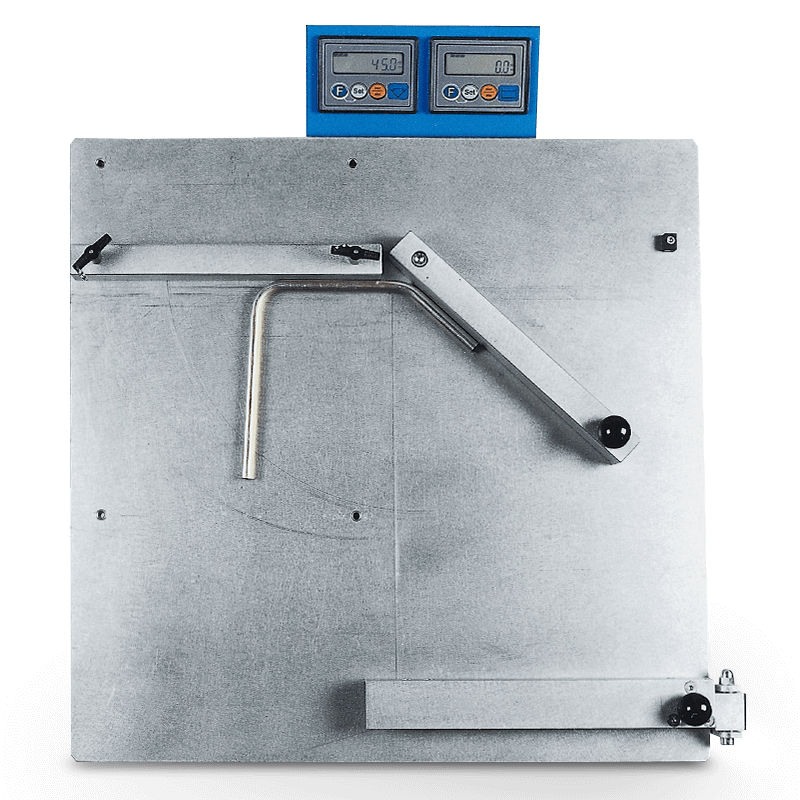

- Plane-of-bend device with three-jaw chuck (or mechanic collet chuck) and length stop device

- 2‑axis measuring system for the length and rotational position with digital displaying

- Follower-type pressure die (sliding guide)

- Anticipated mandrel retraction for optimising the bend quality

- Manual or automatic mandrel lubrication

- Pipe bending software PIPEFAB BE (Bending Edition) for installation on an external PC

- Pipe saw with line laser saw cut visualisation, adjustable saw feed and folding saw blade protection cover

- Internal and external pipe end deburring unit, mounted in an optimised position

- Universal seating device (as basic adapter for adding on a cutting ring assembly or flaring unit), swivelling for an optimised accessibility

- Electronically controlled cutting ring assembly unit (with manual or automatic pressure adjustment)

- Flaring unit for 37 ° SAE flares

- Pipe length (over mandrel): 1500 mm / 3000 mm / 4500 mm / 6000 mm