ROBOFIX Positioning system for flange pipe / template pipe manufacturing

Insight ROBOFIX

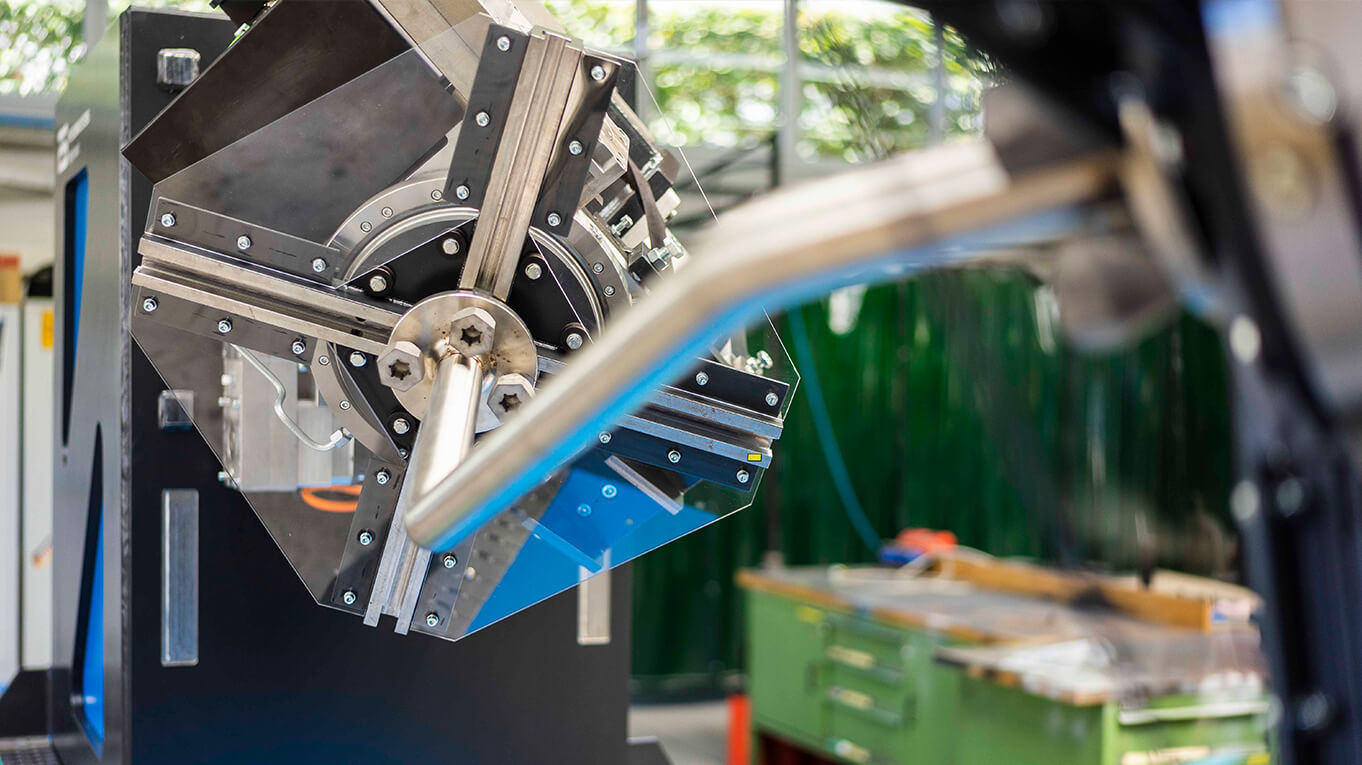

Positioning system for flange tacking of fitting pipes in the correct position

By means of the ROBOFIX System the position of the flanges can be precisely simulated at the workshop, so that the distance and alignment of

the flange planes and the hole pattern correspond exactly to the actual installation situation on the construction site. Positioning of the flanges can be executed using the geometrical data previously generated on site through isometric sketching by the SCOPELINK measuring system. The required pipe can be produced by an assembly of segments or by bending, it has to be positioned between the flanges and fixed to them by tack-welding. The quality assurance of the whole operation is carried out by the ROBOFIX System which controls continuously the accuracy of flange positions and pipe courses.

The pipe, manufactured from segments or by bending, is positioned correctly between the flanges and joined to them by tack welding. The ROBOFIX system ensures the quality of the entire fitting pipe manufacturing process, as compliance with the flange positions and pipe routing is constantly monitored.

After welding the flanges on a Welding station, the completely prefabricated fitting pipe can be taken to the construction site, where it can be perfectly integrated into the piping system.

ROBOFIX Positioning system for flange pipe / template pipe manufacturing

The advantages

ROBOFIX DN 400 in numbers

Technical data

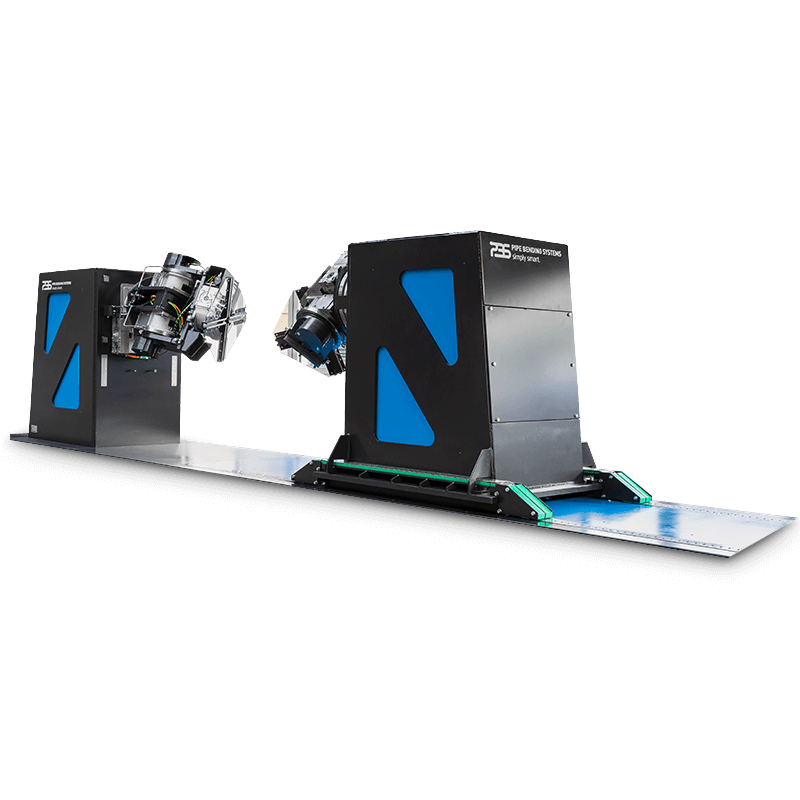

| MASCHINENTYP | ROBOFIX DN 400 | ROBOFIX DN 100 | ROBOFIX DN LIGHT |

|---|---|---|---|

| Maximum travel of the gantry | 400 — 2000 mm | 300 — 1600 mm | 300 — 1600 mm |

| Positioning accuracy of the gantry | ± 0,1 mm | 0,05mm | - |

| Maximum pipe weight | 400 kg | 48 kg | 25 kg |

| Rotation of the 3D flanges | ± 90° | ± 90° | ± 90° |

| Positioning accuracy of the 3D flanges | ± 0,1° je Freiheitsgrad | ± 0,05° je Freiheitsgrad | - |

| Flange adapters | DN40 — DN400 | DN25 — DN100 (DN125) | DB25 — DN 100 |

| Dimensions, approximately | 7200 x 1300 x 2200 mm | 5500 x 1000 x 1800 mm | 2300 x 620 x 800 mm |

| Weight, approximately | 8000 kg | 4000 kg | 250 kg |

| Connected load | 16,0 kW | 19,0 kW | - |

- Hochpräzise räumliche Positionierung der Anschlussflansche für ein Passrohr entsprechend der vor Ort aufgemessenen Einbausituation

unter Berücksichtigung von Winkellage und Lochbild - Direkt Übernahme der mit dem SCOPELINK Isometriersystem ermittelten Positionierungsdaten

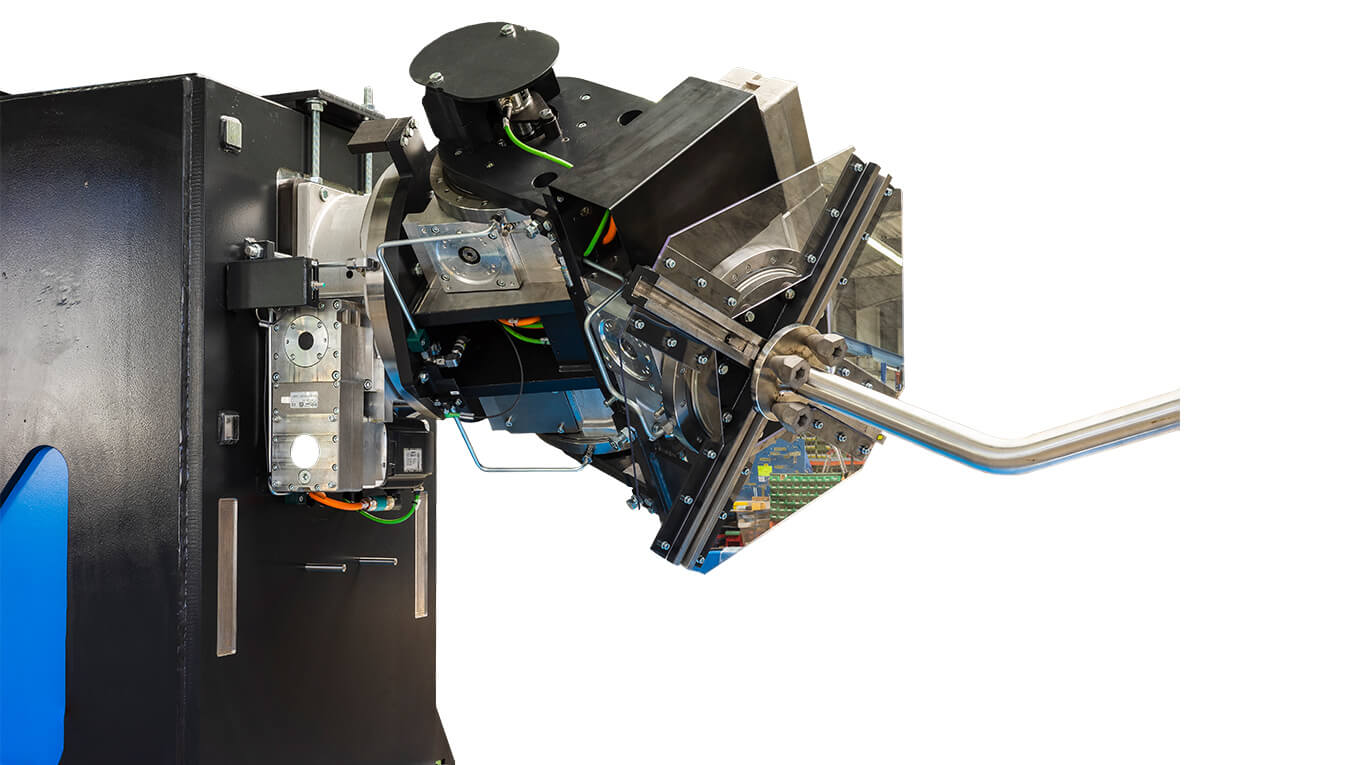

- Traverse mit präziser Linearführung, über Servomotoren angetrieben

- 3D Flansche mit halbkugelförmiger Ausrichtung, über Servomotoren angetrieben

- Hydraulische Feststellbremse zur sicheren Fixierung der Einbaulage

- Verfahrbares Bedienpult mit Steuer-PC, vorinstallierter Steuer- und Visualierungs-Software

- Integrierte Kollisionskontrolle

- ROBOFIX DN 100

- ROBOFIX Light