A system must be scalable

Intelligent system solutions for pipe processing

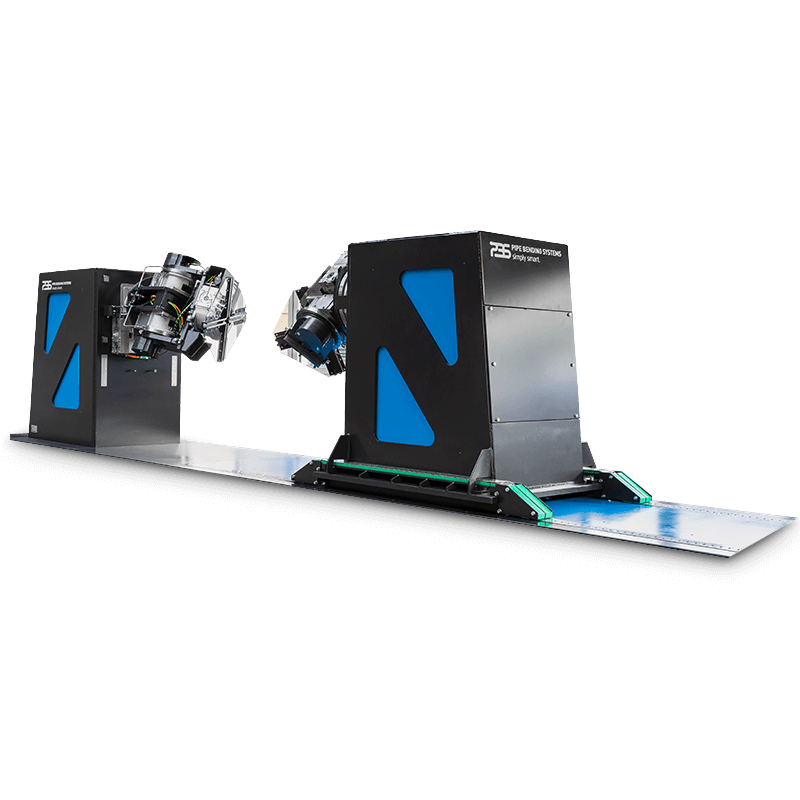

The pipe bending system from PBS

A system must be scalable.

For more than five decades, TRACTO-TECHNIK has been a reputable partner in processing pipes. During this time we have acquired extensive experience in pipe forming techno-logy. This led to the development of the system for process-ing media-carrying pipes: PIPE BENDING SYSTEMS. This reflects our core competence: Thinking in terms of system solutions for pipe processing. The best system for single-part and small-series production with great product variety.

Innovative pipe bending systems

guarantee process reliability

PIPE BENDING SYSTEMS consists of four components that work together to make the system reliable, accurate, forward-looking and satisfying:

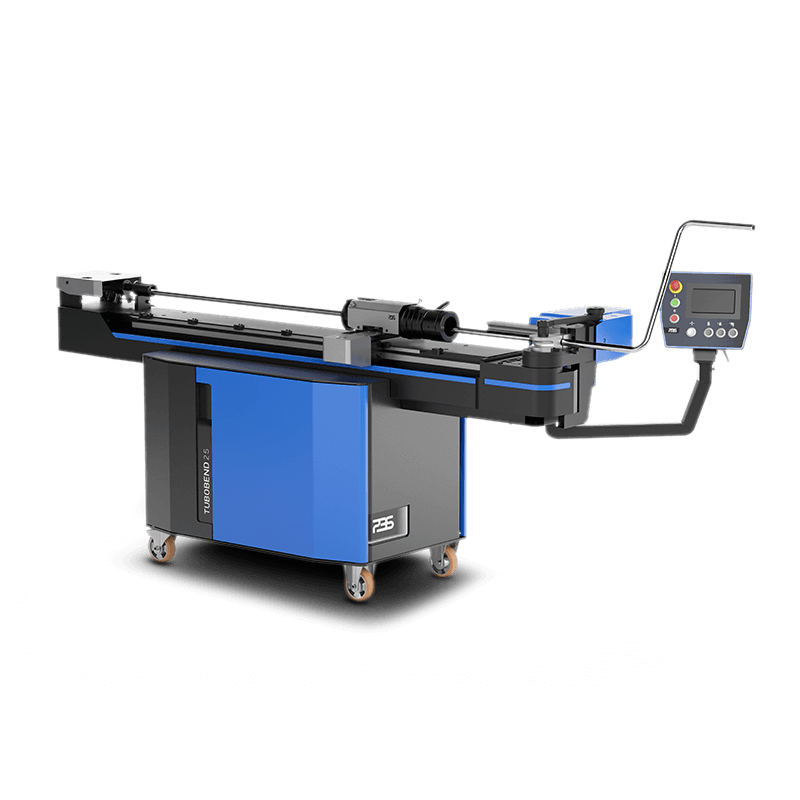

- Innovative pipe bending machines

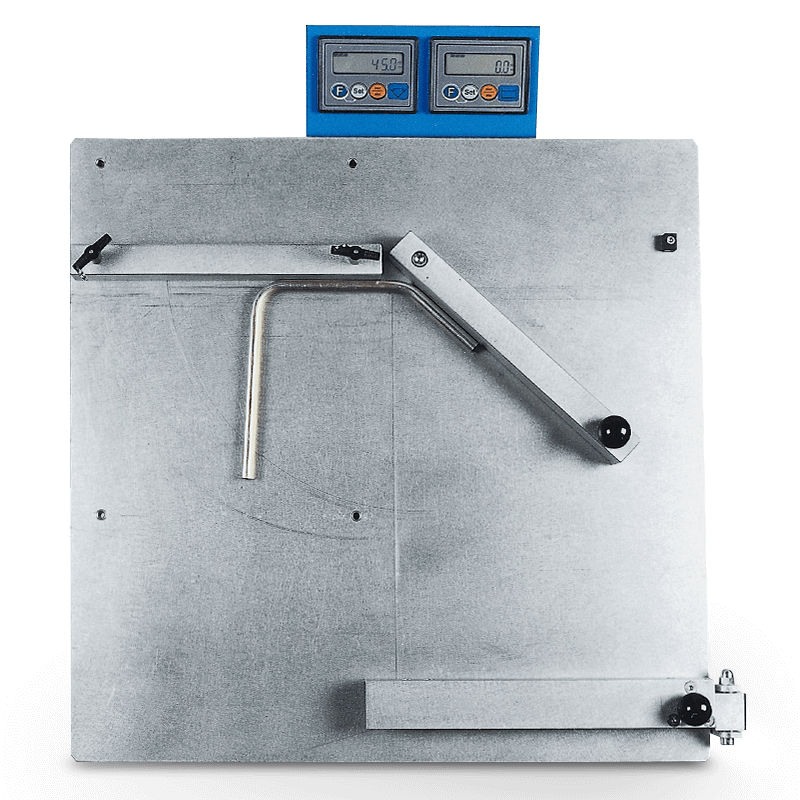

- High precision pipe measurement technology

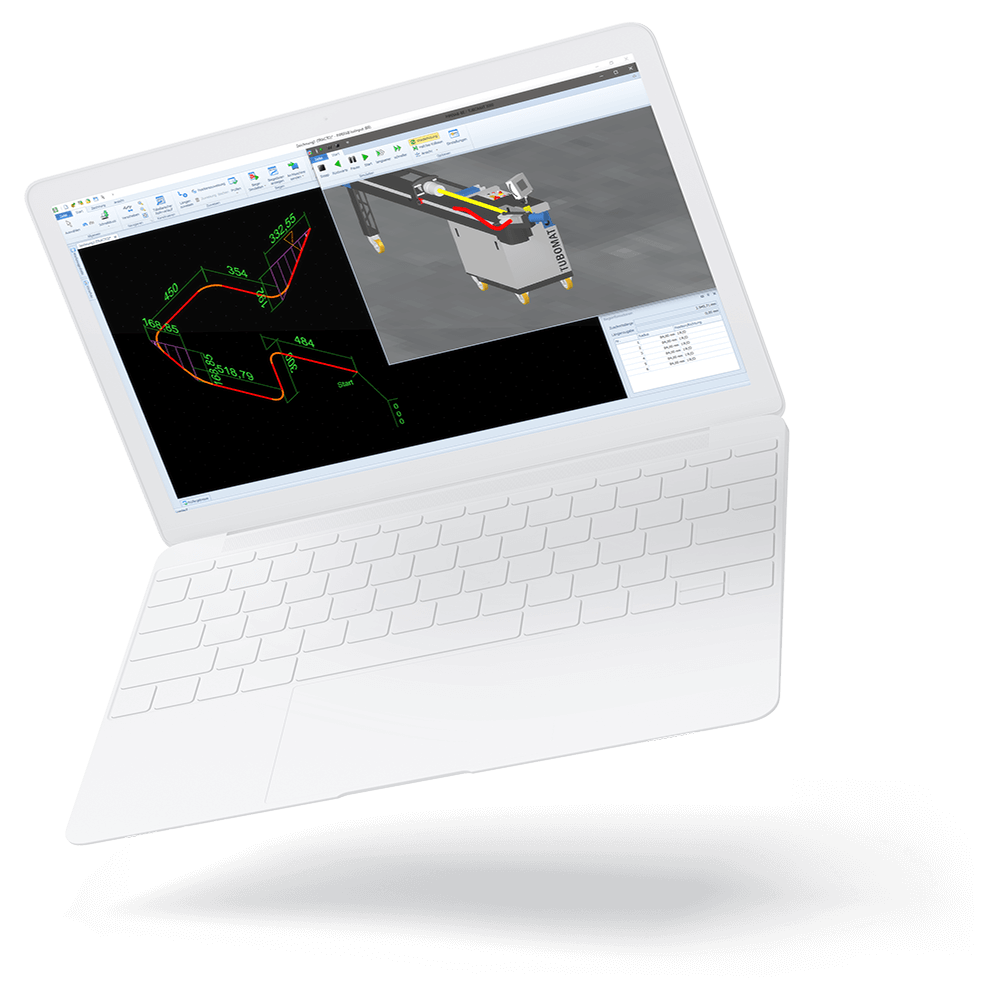

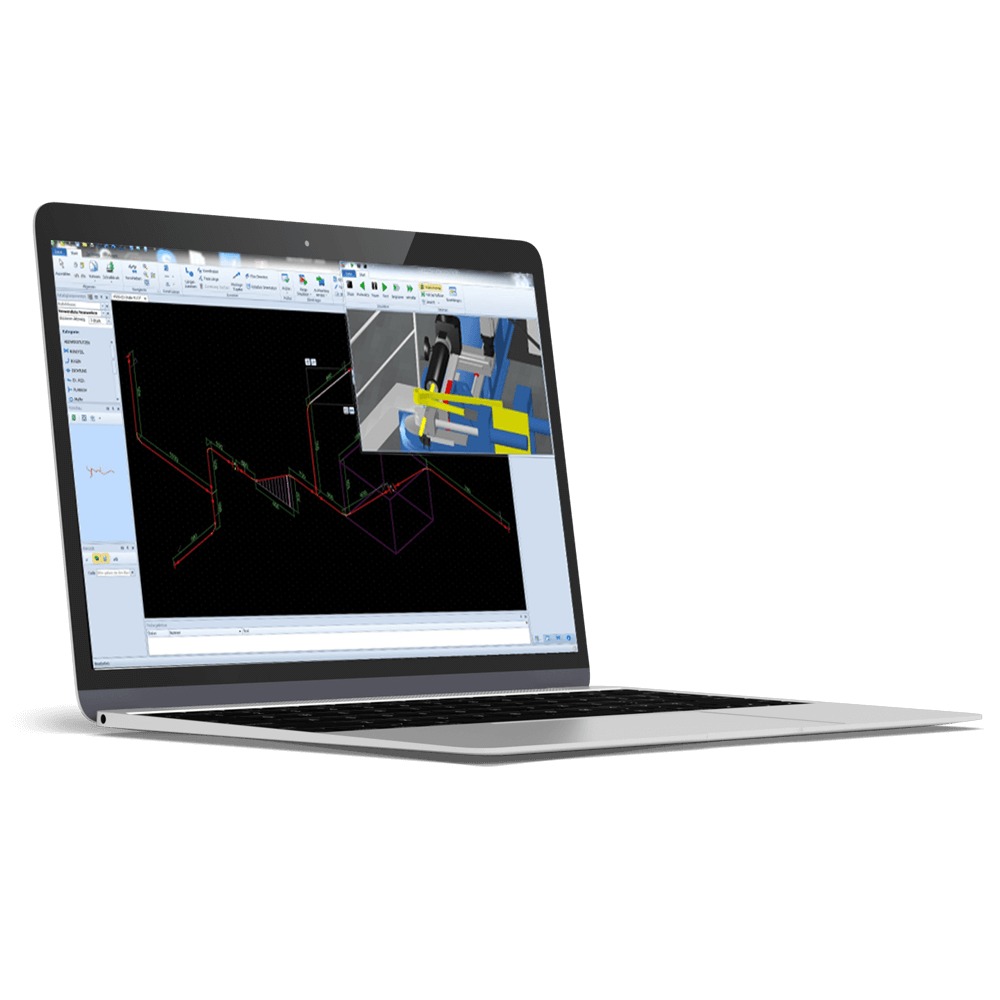

- Efficient software solution

- Exzellent service

For out customers, we realize a smoothly functioning overall system — intelligent and uncomplicated, simply smart. As a system provider and expert for integrated fitting piping and pipe prefabrication, we take into account all aspects for efficient, cost-effective and process-reliable pipe processing: Innovative machines, precise measuring systems, intelligent software solutions as well as excellent consulting and Service are available to our customers for all projects from the very beginning.

PIPE BENDING SYSTEMS

The right

System for

your requirements

What are you looking for a solution for?

Please click on one of the tiles

Ausbauschritt 1

PIPE MANUFACTURING

Typical production steps of pipe manufacturing are sawing and bending as well as end preparation or cutting ring assembly. In order to achieve a high degree of flexibility in the piping process on site (on the construction site, at the plant), a good coordination of the processes without fixed interlink-ing is optimal. The robustness of the processes and thus of the machine technology is ensured by high-quality machine technology.

Ausbauschritt 2

SOFTWARE-SUPPORTED PIPE

MANUFACTURING

A significant improvement in the tube manufacturing process is achieved by linking technological data from the process steps of sawing, bending and quality assurance.

Ausbauschritt 3

SOFTWARE-CONTROLLED PIPE

MANUFACTURING

High efficiency of manufacture planning and controlling of individual pipes or small series can be achieved if technological and administrative data are linked together. Numerous production steps from storage to pipe preparation, machining and installation can be coordinated and managed.

Linking together technological and administrative data enables the creation of production batches. These production batches can be optimised according to requirements, costs, lead times or re-sources. The optimal value chain is selected for the defined boundary conditions.

Ausbauschritt 4

AUTOMATED PIPE MANUFACTURING

The networking of the technological and organizational information of all process steps of tube production allows an automation of the processes even for single piece or small series production. All process steps can be linked from the warehouse to pipe preparation, pipe processing and assembly on site.

In the warehouse logistic processes like control of transport, commissioning and storage can be affected. The pipe preparation may comprise separation, deburring and cleaning. Machining can consist of pipe bend-ing, end processing, cutting ring assembly, joining (welding), flaring, and related quality assurance opera-tions. In the production step of assembling the integration of logistic processes like commissioning and component tracking can support the overall automation.